CHARACTERISTICS

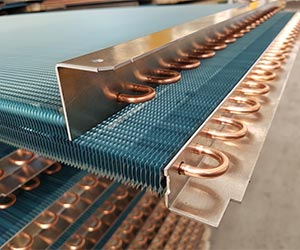

We develop and produce heat exchangers to order using different geometrical configurations, materials and construction features to satisfy all our customers’ needs.

COMPANY

Over 200 qualified people who work in a highly professional and coordinated manner.

WHY YOU SHOULD CHOOSE EUROCOIL

Rapid, reliable deliveries

Speed of production and respect of agreements have always been a strong point of our company.

Flexibility

A lean, well-organized business structure that ensures flexibility in both product development and in orders fulfillment.

Technical support and the ability to suggest solutions

With a staff of competent experts constantly updated, we are able to provide good support both for correct thermodynamic sizing and the development of flexible technical solutions, ideal to resolve the customer’s specific problems.

High quality standards

Expert, highly motivated personnel, equipped with modern tools and state-of-the-art machinery, enable us to guarantee compliance with the strictest quality standards.

Advanced machinery and equipment

We invest every year, in a programmed and continuous way, to maintain our equipment up-to-date and efficient.

Qualified personnel

Our personnel are carefully selected and follow a targeted, continuous training program to ensure that they achieve and maintain a high quality level.

CERTIFICATION

The organization and the standardization of the processes guarantee the quality of the products and the safe execution of the workings. This is why Eurocoil is certified according to the standard UNI EN ISO 9001:2015 and UNI ISO 45001:2018.

Heat exchangers can be approved for the North American market according to UL 207 – CAN / CSA C22.2.

NEWS

Production line for CO2 and ammonia heat exchangers

The growing interest in these natural fluids finds in Eurocoil an ideal partner.

In addition to propane exchangers, we can produce evaporators and gas-coolers for CO2 with PS=120 bar and condensers with stainless steel tube for NH3, in order to be a reliable supplier for commercial and industrial refrigeration.

Tube 5 and 7 mm

These diameters allow to reduce the amount of refrigerant and raw material and the production of heat exchangers with high efficiency thanks to the particular shape of the fin and the accurate design of the circuit, suitable for flammable refrigerants such as propane (R290).

Baltimore Aircoil Company acquires Eurocoil SPA

Baltimore Aircoil Company (BAC), a leader in cooling solutions worldwide for the commercial, industrial, and refrigeration markets, announced the acquisition of Eurocoil SPA. Read more…