CHARACTERISTICS

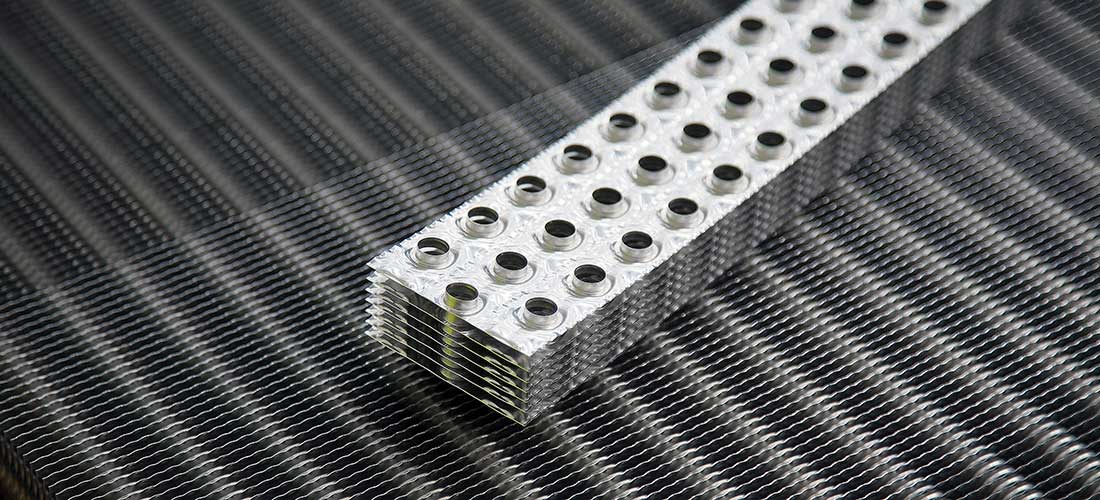

FINNED COILS IN 9 DIFFERENT GEOMETRICAL CONFIGURATIONS

We produce finned coils for heat exchange between air and a primary fluid according to the drawings or technical specifications supplied by the customer.

Advanced engineering systems, state-of-the-art technical know-how and experience enable us to offer the most appropriate solutions from the technical and economic standpoint.

The geometrical configurations and construction possibilities are listed in the tables below.

Eurocoil systems can be manufactured with:

- copper tube of different thicknesses and with smooth or inner grooved surface;

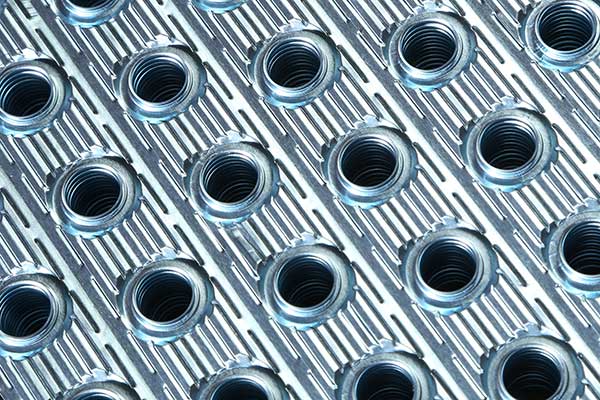

- fins, with self-spacing collar, in aluminum, pretreated aluminum or copper;

- carpentry in galvanized sheet metal, stainless steel, copper, brass or aluminum;

- copper manifolds with connectors for welding or with threaded couplings depending on the application.

All heat exchangers are tested at 10 bar if functioning with water or at 30-50 bar if functioning with refrigerants.

We produce CO2 heat exchangers, testing them at 100% in accordance with standard 2014/68/UE (PED).

On request they can be tested under different conditions.

GEOMETRICAL CONFIGURATIONS

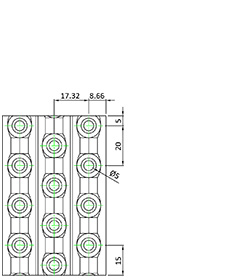

0517

Tube pattern: staggered

Corrugated and louvered fin

TUBE DIAMETER

5 mm

FIN PITCH

Min. 1,4 mm – Max 4,0 mm

TUBE MATERIAL

Copper

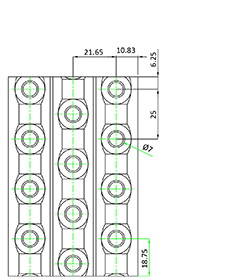

0722

Staggered tube arrangement.

Corrugated and louvered fin

TUBE DIAMETER

7 mm

FIN PITCH

Min. 1,4 mm – Max 4,0 mm

TUBE MATERIAL

Copper

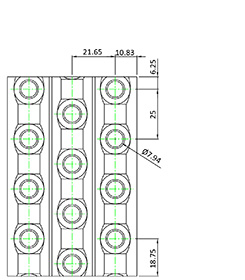

0822

Staggered tube arrangement.

Corrugated and louvered fin

TUBE DIAMETER

5/16” – 7,94 mm

FIN PITCH

Min. 1,6 mm – Max 5,0 mm

TUBE MATERIAL

Copper

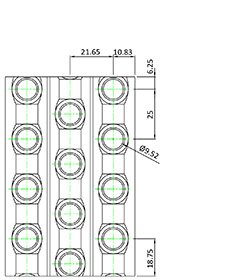

2522

Staggered tube arrangement.

Corrugated and louvered fin

TUBE DIAMETER

3/8” – 9,52 mm

FIN PITCH

Min. 1,6 mm – Max 5,0 mm

TUBE MATERIAL

Copper – Cupronickel

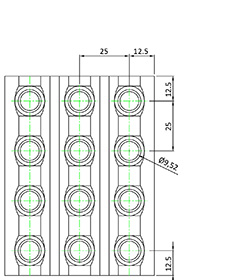

2525

Arranged with tubes in line.

Flat fin

TUBE DIAMETER

3/8” – 9,52 mm

FIN PITCH

Min. 1,6 mm – Max 5,0 mm

TUBE MATERIAL

Copper – Cupronickel

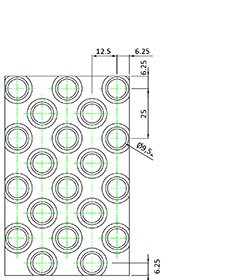

2512

Staggered tube arrangement.

Flat fin

TUBE DIAMETER

3/8” – 9,52 mm

FIN PITCH

Min. 1,6 mm – Max 3,2 mm

TUBE MATERIAL

Copper

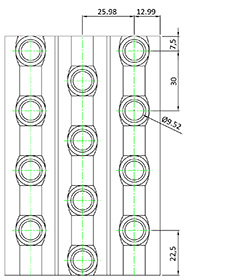

1026

Staggered tube arrangement.

Corrugated fin

TUBE DIAMETER

3/8” – 9,52 mm

FIN PITCH

Min. 1,6 mm – Max 4,2 mm

TUBE MATERIAL

Copper

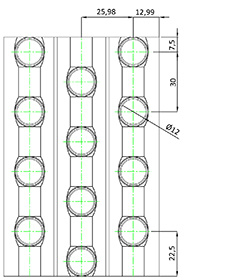

1226

Staggered tube arrangement.

Corrugated fin

TUBE DIAMETER

12 mm

FIN PITCH

Min. 1,6 mm – Max 4,2 mm

TUBE MATERIAL

Copper

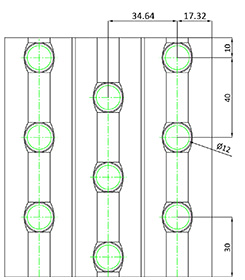

1235

Staggered tube arrangement.

Corrugated fin

TUBE DIAMETER

12 mm

FIN PITCH

Min. 1,6 mm – Max 4,2 mm

TUBE MATERIAL

Copper – Stainless Steel

MATERIAL OPTIONS

Flat aluminum

Standard application.

Treatments such as heresite or cataphoresis are possible.

Geometrical configurations 2525 and 2512.

Corrugated aluminum

Standard application.

Treatments such as heresite or cataphoresis are possible.

Geometrical configurations 0517, 0822, 2522, 1026 e 1226.

Louvered aluminum

Standard applications; louvers increase the exchange coefficient on the air side.

Geometrical configurations 0517, 0822 and 2522.

Flat hydrophilic surface

In coils for air cooling, this treatment prevents natural oxidation of the aluminum, improves drainage of condensate and reduces the air pressure drop.

Geometrical configurations 2525 and 2512

Corrugated hydrophilic surface

In coils for air cooling, this treatment prevents natural oxidation of the aluminum, improves drainage of condensate and reduces the air pressure drop.

Geometrical configurations 0517, 0822, 2522, 1026 and 1226.

Louvered hydrophilic surface

This treatment prevents natural oxidation of the aluminum, improves drainage of condensate and reduces the air pressure drop; louvers increase the exchange coefficient on the air side.

Geometrical configurations 0517, 0822 and 2522.

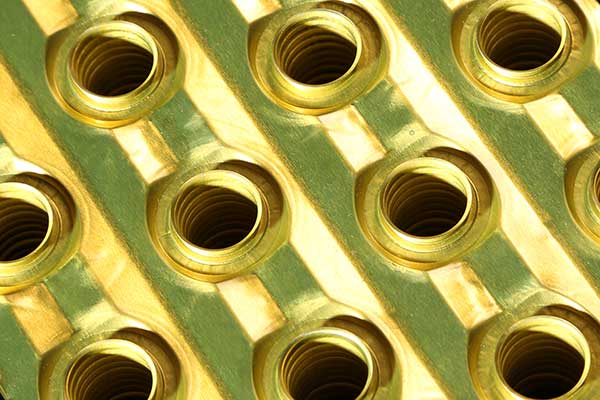

Flat Goldlack

Prevents oxidation and protects against certain corrosive agents.

Geometrical configurations 2525 and 2512.

Corrugated Goldlack

Prevents oxidation and protects against certain corrosive agents.

Geometrical configuration 0517, 0822, 2522, 1026 and 1226.

Flat prepainted surface

Offers good protection in a saline environment or one with high humidity and other corrosive agents; resistant to UV rays.

Geometrical configuration 2525 and 2512.

Corrugated prepainted surface

Offers good protection in a saline environment or one with high humidity and other corrosive agents; resistant to UV rays.

Geometrical configuration 0517, 0822, 2522, 1026 and 1226.

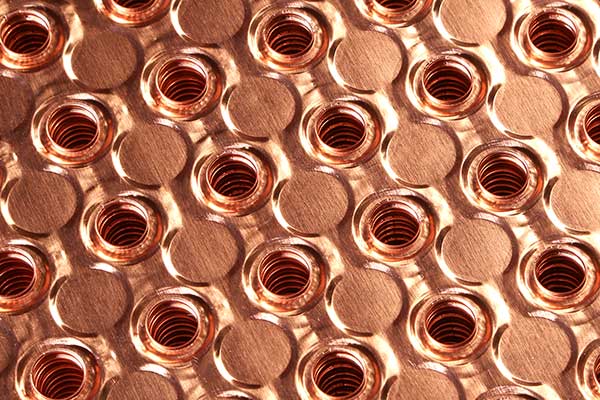

Flat copper

Recommended for marine environments or swimming pools or where greater mechanical strength of the fins is required.

Geometrical configuration 2525 and 2512.

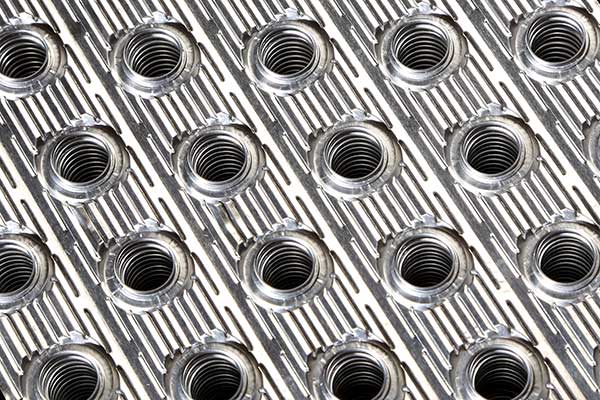

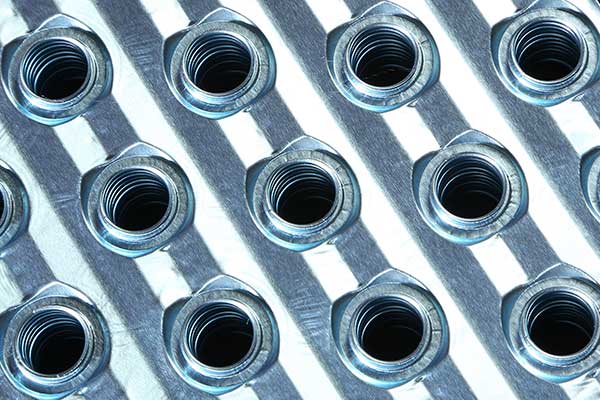

Corrugated copper

Recommended for marine environments or swimming pools or where greater mechanical strength of the fins is required.

Geometrical configuration 0517, 0822, 2522, 1026 and 1226.