PRODUCTS

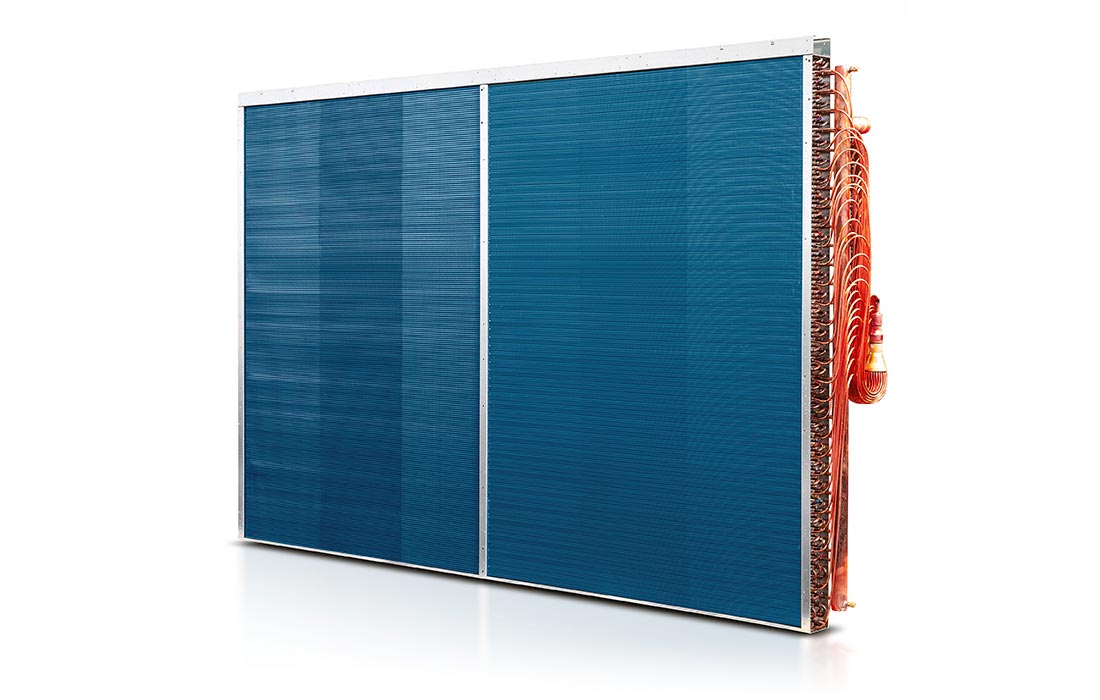

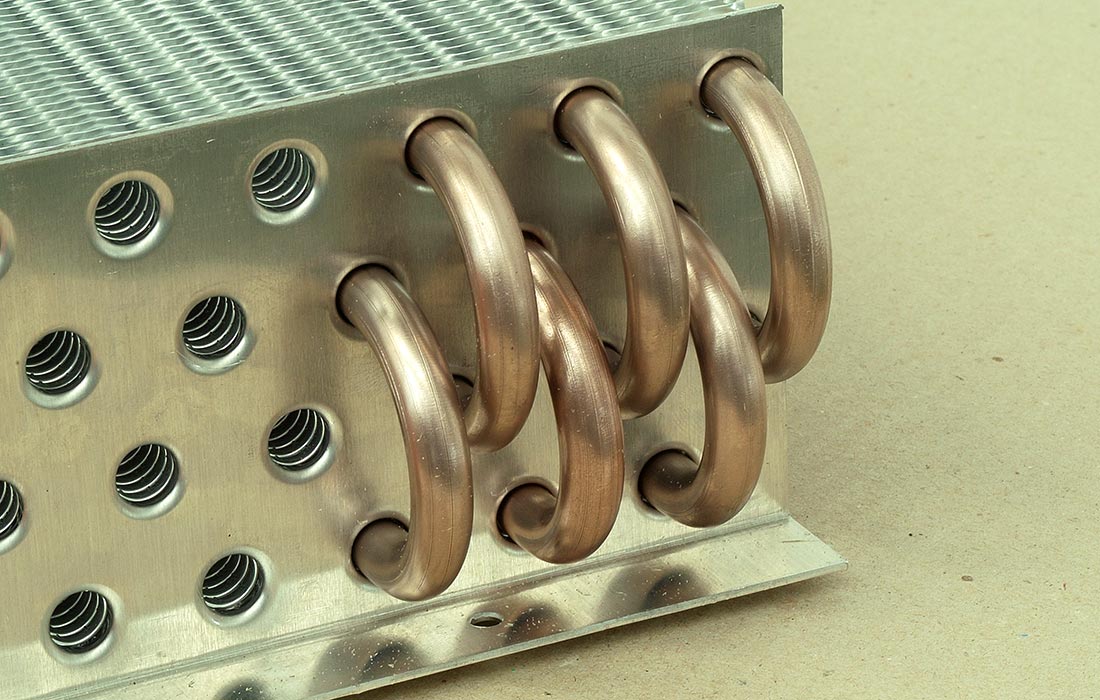

FINNED BLOCK HEAT EXCHANGERS

We construct finned block heat exchangers up to 12 meters in length, using carefully selected materials from primary suppliers, on the basis of strict quality specifications.

Production is handled with advanced equipment including numerically controlled machines, using accurately inspected processes that we strive to improve constantly.

Large resources are invested annually for the training and promotion of what is the company’s most important capital: its personnel.

FINNED COILS MADE TO MEASURE

SPECIAL DESIGNS

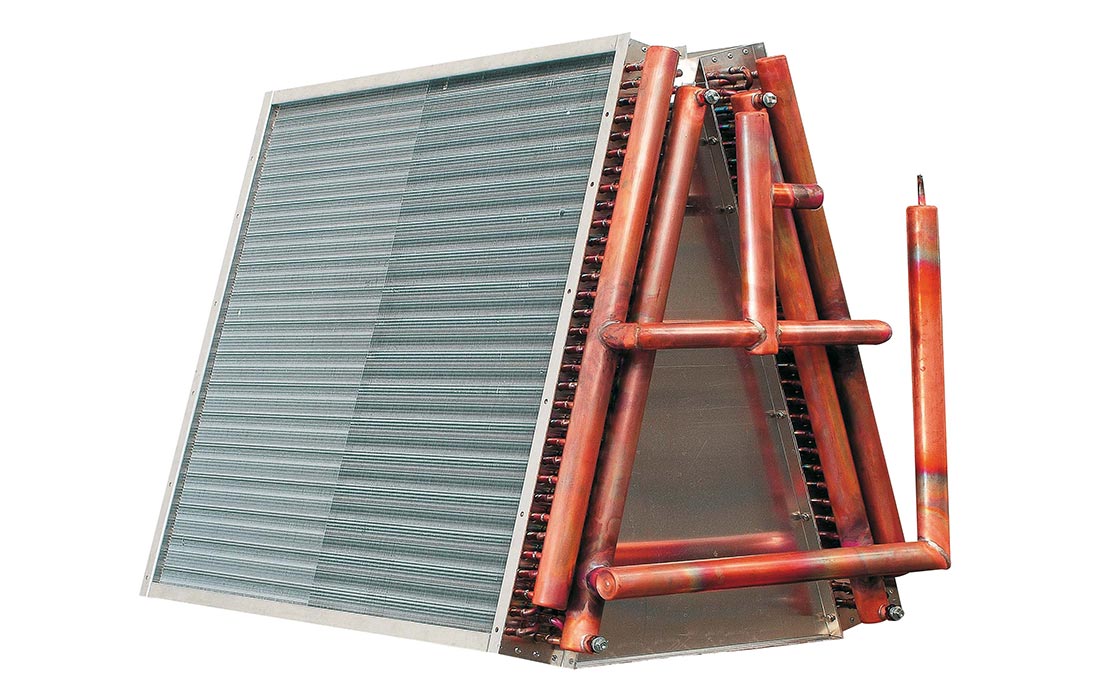

REMOTE CONDENSERS AND LIQUID-COOLED CONDENSERS

Air condensers:

PEC – for R410A

PDC – for R404A and other HFC refrigerants

Dry coolers:

PWD

Characteristics:

- Power from 6kW to over 230 kW (according to EN327 directive).

- Fans ø 350 mm and ø 500mm.

- Wide range to satisfy all needs in terms of output, space and noise.

- All products manufactured according to EC and PED regulations.

- Internal framework in aluminum and external hull in galvanized steel powder painted RAL 9002.

- Possibility to configure the product with various options such as cut phase speed controllers or electronic fans, anticorrosive treatment of the finned block and other customizations.

Air condensers:

PEC – for R410A

PDC – for R404A and other HFC refrigerants

Dry coolers:

PWD

Characteristics:

- Power from 20kW to over 900 kW (in accordance with directive EN327).

- Fans ø 630 mm and ø 800mm.

- Wide range to satisfy all needs in terms of output, space and noise.

- All products built according to EC and PED regulations.

- Sturdy frame in galvanized sheet metal with system of protection for copper pipes. External hull in galvanized steel powder painted RAL 9002.

- Possibility to configure the product with various options such as cut phase speed controllers or electronic fans, anticorrosive treatments of the finned block and other customizations.

SECTORS OF APPLICATION

Hydronic air treatment systems

The heat exchangers work with hot or cold water to heat or cool/dehumidify the room air and guarantee conditions of wellbeing.

Home and industrial air conditioning

Finned evaporating coils are normally used to cool and dehumidify, and finned condensing batteries to release heat to the external environment.

Thermal control of processes

In this case, air is used to cool and thus control the temperature of the process fluid.

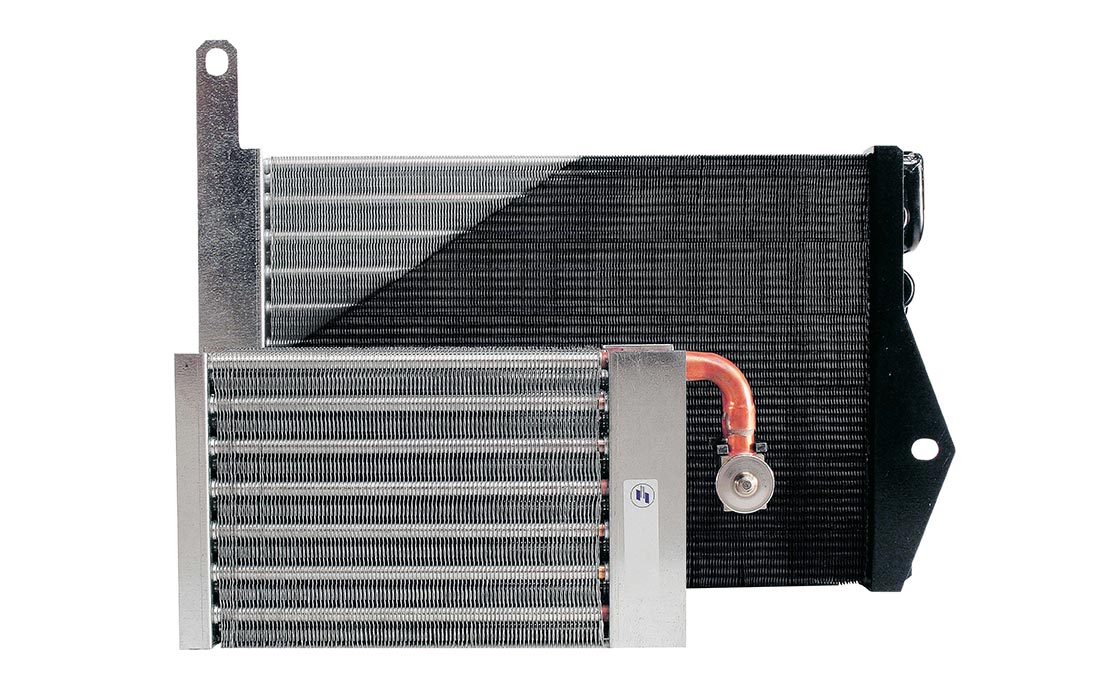

Automotive air conditioning

The operating principle is the same as that for home air conditioning, with particular attention to reducing the dimensions of the heat exchangers, in consideration of the limited space available.

Refrigerated transport

This process contemplates the use of evaporators and condensers to guarantee the conservation of the product at temperatures as low as – 30°C, installed on containers or special cold shipment vehicles.

Heat pumps

The operating principle is that of air conditioning, also heating the water or air.

Telephone systems and close-control

In this case, evaporators and condensers serve to maintain room temperature within the correct and precise limits required for electronic equipment, telephone systems and data processing centers.

Special applications

These include all those applications not listed above or that use special materials or particular surface treatments.